How Quality Control so importance in Apparel Creation

How Quality Control so importance in Apparel Creation

In the fast-paced world of fashion and apparel, where trends shift rapidly and consumer expectations soar, quality control (QC) stands as a non-negotiable pillar of success. From high-end luxury brands to affordable fast-fashion retailers, ensuring consistent product quality is critical to maintaining customer trust, reducing costs, and safeguarding brand reputation. Here’s why quality control is indispensable in clothing manufacturing:

—

1. Protects Brand Reputation

A single defective product can tarnish a brand’s image overnight. In the age of social media and online reviews, dissatisfied customers are quick to share negative experiences. For example, a zipper that breaks after one use or fabric that shrinks irregularly can lead to viral complaints. Rigorous quality control processes—such as pre-production fabric testing, in-line inspections during sewing, and final garment checks—help catch flaws early, ensuring only flawless products reach consumers. Brands like Patagonia and Zara invest heavily in QC to uphold their reputations for durability and style, respectively.

—

**2. Reduces Costs in the Long Run

While skipping quality checks might save time and money initially, it often leads to costly consequences later. Defective garments result in returns, refunds, and wasted inventory. For instance, a batch of misdyed fabrics discovered post-production could force a company to discard entire stock or sell it at a loss. By implementing QC at every stage—from raw material sourcing to final packaging—manufacturers avoid rework, minimize waste, and improve operational efficiency.

—

**3. Builds Consumer Trust and Loyalty

Today’s shoppers prioritize quality over quantity. A 2022 McKinsey report revealed that 65% of consumers are willing to pay more for clothing that lasts longer. Consistent quality assurance signals to customers that a brand values their satisfaction. For example, outdoor apparel companies like The North Face use QC to ensure waterproof seams and reinforced stitching, earning loyal customers who trust their products in extreme conditions.

—

**4. Ensures Compliance with Standards

Clothing manufacturers must adhere to strict international safety, ethical, and environmental regulations. Quality control processes verify compliance with standards such as OEKO-TEX® (for harmful substance testing) or Fair Trade certifications. Failure to meet these requirements can lead to legal penalties, recalls, or bans. For instance, in 2023, a major fast-fashion brand faced backlash when a supplier was found using toxic dyes, highlighting the consequences of lax QC.

—

**5. Supports Sustainability Goals

The fashion industry is under increasing pressure to reduce its environmental footprint. QC plays a pivotal role in sustainability by minimizing waste and extending product lifecycles. For example, checking fabric strength during production ensures garments withstand repeated wear, reducing the likelihood of premature disposal. Brands like Eileen Fisher use QC to maintain high standards for their recycled-material collections, aligning with their eco-conscious ethos.

—

6. Enhances Supply Chain Relationships

Quality control fosters transparency and accountability between brands, manufacturers, and suppliers. Clear QC protocols prevent disputes over defective batches and build long-term partnerships. For instance, luxury brands like Louis Vuitton work closely with factories to enforce strict QC measures, ensuring every handbag or jacket meets their exacting standards.

—

**7. Adapts to Fast Fashion’s Demands

In fast fashion, speed often clashes with quality. However, brands like H&M and Uniqlo prove that QC can coexist with rapid production cycles. Automated technologies, such as AI-powered defect detection systems, enable real-time monitoring of stitching accuracy or pattern alignment. This balance allows companies to deliver trendy, affordable clothing without compromising on quality.

—

**The Hidden Costs of Ignoring QC**

Neglecting quality control risks more than just financial loss. It erodes consumer confidence, damages relationships with retailers, and undermines sustainability efforts. For example, Shein, despite its popularity, has faced criticism for inconsistent sizing and poor fabric quality—issues that could be mitigated with stronger QC practices.

—

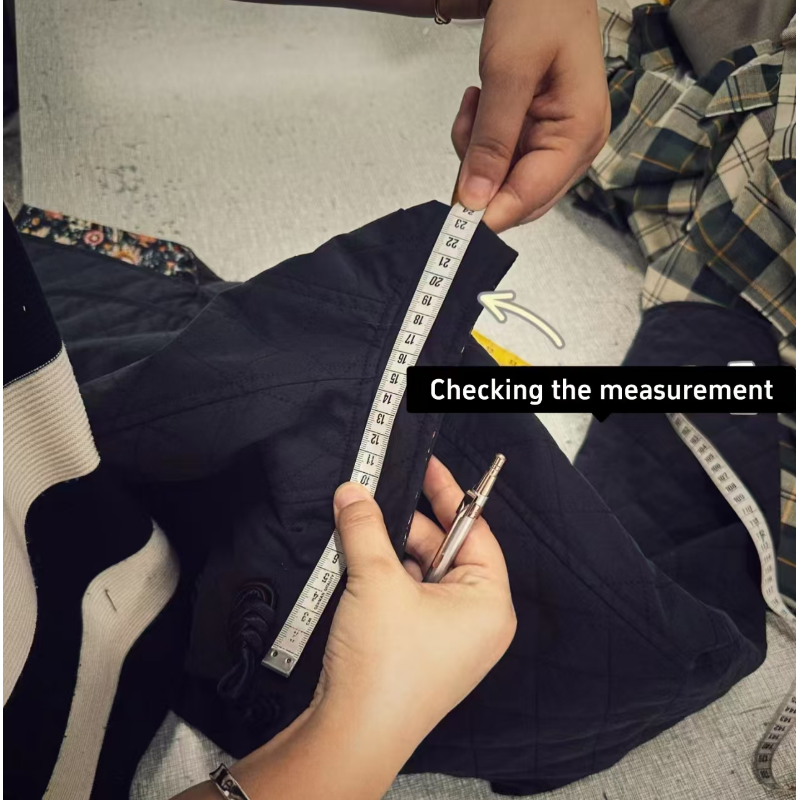

**Implementing Effective Quality Control**

To maximize QC’s impact, brands should:

– **Set clear quality benchmarks** (e.g., tolerance levels for stitching errors).

– **Train staff and suppliers** on QC protocols.

– **Leverage technology**, such as 3D imaging for defect detection.

– **Conduct third-party audits** for unbiased evaluations.

—

**Conclusion**

Quality control is not just a step in the manufacturing process—it’s a strategic investment in a brand’s future. By prioritizing QC, clothing manufacturers can deliver products that delight customers, foster loyalty, and stand the test of time. In an industry where reputation is everything, quality control isn’t optional; it’s the thread that weaves success into every garment.